|

|

|

|

|

|

|

|

|

|

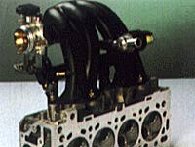

Thanks to new technical plastics, which withstand high temperatures and make optimum use of new processing techniques, more and more of functional engine parts are being produced in composite materials. Solvay was among the first in Europe to set up an industrial production line for thermoplastic parts using the fusible-core or the vibration-welding injection technique. This allows the production of parts with complex shapes and compliance with very severe specifications. Driven by a fully integrated system approach, Solvay Automotive companies provide their customers with a complete plastic module for the air intake function. Made using sophisticated technologies, this module is fully equipped with air intake manifold, resonator, air filter, air ducts, fuel rail, injectors, etc. This system has major advantages : better design, better engine output, lower weight and thermal conductivity, fewer components, and less assembly work by the car maker. All of this amounts to lower costs and less material waste. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The reasonator on the 1996 Dodge Neon is blow molded from NORYL GTX ® resin manufactured by GE Plastics. NORYL GTX® resin gives the application high heat and chemical resistance, and the blow molded design helps reduce engine noise. |

|

|

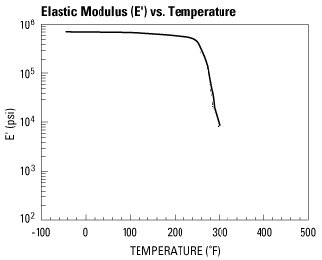

NORYL GTX resin is part of a family of engineering thermoplastics manufactured by GE Plastics that cover the spectrum of performance requirements in the demanding environment of powertrain applications. Along with a polyester polybutylene terephthalate resin and a polyetherimide resin, NORYL GTX resin fills a niche role in the powertrain segment. One recent example of NORYL GTX resin's performance is the resonator on the 1996 Dodge Neon. Both the 2.0 liter double overhead cam and single overhead cam engine options for Neon utilize a blow molded resonator. The decision to specify this resin was based in part on its chemical resistance properties, hydrolytic and dimensional stability characteristics and its ability to withstand temperatures from -40 to 300°F. GE Plastics optimized the blend of polyphenylene oxide and polyamide resins to give a competitive performance advantage over nylon resins. To meet the specification, the part was also required to pass automotive chemical resistance tests for automotive fluids such as oil and antifreeze. Of primary concern to underhood and powertrain engineers are high heat and chemical breakdown of component materials. Resins are a cost effective material that is engineered to meet these specific challenges. With a heat deflection temperature of 363°F, they can withstand the elevated temperatures that can be generated by a high performance engine. Additionally, very good resistance against chemical breakdown from automotive fluids makes resins a logical choice for applications such as engine resonators. Another factor in the material specification were resins impressive processing capabilities versus nylon that allow it to be injection molded or blow molded. Steere Enterprises of Tallmadge, Ohio, chose the blow molding process because it was quicker to manufacture and less expensive than injection molding. Tooling cost savings were approximately 15%, and 10 to 20% faster cycle times were achieved versus competitive materials in the application. Blow molding provides the resonator application with important sound-absorbing properties that can help minimize the engine noise that reaches the passenger compartment. NORYL GTX resin was specified for the resonator application because it combines good mechanical properties with overall system cost savings in automotive powertrain applications, and resins are a versatile material that is engineered to perform in the demanding environment of powertrain applications. |

|

|

|

|