|

|

|

|

|

|

|

|

|

|

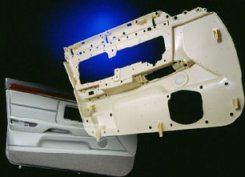

A PC/ABS resin has been specified for the 1997 Cadillac DeVille front door interior trim panel. This PC/ ABS resin was chosen for this application due to its ability to take higher loads and higher heat than ABS or polypropylene. This material advantage led to the specification of resin over competing materials. The PC/ABS resin offers a unique balance of stiffness and ductility that meet these material requirements better than more traditional materials such as ABS or polypropylene. This door trim panel application exemplifies how engineering thermoplastic resins can contribute to not only the aesthetics of a vehicle's interior, but also to the functionality that automotive designers now require from interior components as they design vehicles to satisfy consumer demand for safety and comfort. Molded-in hooks, which hold the trim panel tightly to the door itself to prevent rattles, were a functional feature that required the higher performance characteristics that resin offered over competing materials. The door panel is also made functional by the fact that it carries a speaker, has molded- in support for the arm rest, and is delivered to the assembly plant with sound barrier material attached. More and more, Tier One suppliers like Manchester Plastics look to their material suppliers for valuable technical support throughout the product development cycle. |

|

|

|

|

|

The one-piece thermoplastic Super Plug™ door module, a manufacturer of engineering thermoplastics, has made its on-car debut with the launch of the 1997 General Motors minivans. These minivans, sold as the Chevrolet Venture, the Pontiac Trans Sport, the Oldsmobile Silhouette, and in Europe, the Opel/Vauxhall Sintra, sport a Super Plug designed specifically for this vehicle platform, but the design can be translated to virtually any other production car or truck. In fact, a forthcoming midsize GM sedan, to be sold as the Chevrolet Malibu and the Oldsmobile Cutlass, will soon launch with its own version of the Super Plug door module. Though vehicle owners may never actually see this new plastic component because it's positioned inside the door, it will offer very good quality over conventional systems, along with serviceability that has already been ranked "best in class." To consumers that means fewer squeaks and rattles from the door, and maybe even fewer trips to the service department. A traditional car door typically houses a complex array of parts that perform many functions vehicle owners take for granted, such as wires and tracks for accommodating the windows and stereo speakers, components for the door locking system, and the frame that provides structure to the door itself. The many intertwining parts make the door an area in a car that is time-consuming and costly to assemble and often dissatisfies customers due to squeaks and rattles and a high incidence of warranty claims. The Super Plug integrates the function of many of these door components into a single thermoplastic part, reducing the number of parts inside the door by up to 75%. With fewer parts inside the door, assembly time is greatly reduced, and servicing the door system is made simpler. However, since the Super Plug's design will differ from one vehicle platform to another, parts integration, assembly improvements and serviceability will also differ from platform to platform, depending on the complexity of a vehicle's door system. |